Automotive and Motorcycle Related Parts

Applications in Wire Cut and CNC EDM machining industries

Wire cut and CNC EDM machines have a wide range of applications in automotive and motorcycle-related products. These include everyday commuting, commercial cargo transportation, and heavy machinery handling. Due to the different purposes of use, the combination and production of related parts can reach millions of variations. With the continuous advancement of technology, the demands for processing quality and details are getting higher and higher. People have different insights into the processing methods compared to the past. The solutions provided by JSEDM have been widely used in various automotive and motorcycle parts brands. To meet the challenges of modularization and refinement, JSEDM can also offer customized machine solutions to meet customers' processing needs.

EDM and Wire cut machines play an important role in the production of automotive and motorcycle parts. EDM (Electrical Discharge Machine) can precisely process complex-shaped parts and molds. It can perform high-precision machining on materials with high hardness and toughness, ensuring the dimensional stability and surface quality of the parts. In addition, Wire cut machines (WEDM) are widely used in mold manufacturing and the cutting of high-precision parts, such as automotive transmission systems, car light reflector molds, and motorcycle wheel molds. Wire cut EDM technology can achieve high-precision cutting of complex contours and can process materials that are difficult to machine using traditional methods.

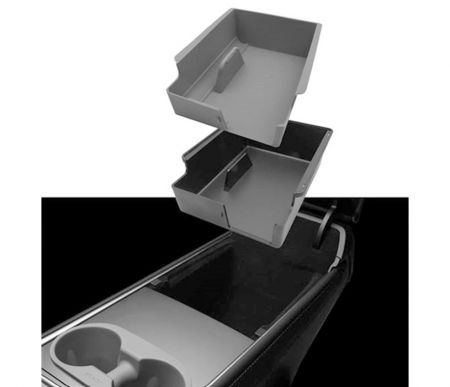

Automotive Interior

Air conditioning module, Buttons, Cup holder, Seat belt, Steering wheel gear shift lever, Door module, Central console and dashside module.

Automotive Related Parts and Accessories

Storage box, Cup holder, Plastic floor mats, Expansion hub for charging, Joystick, Screen protector mold fixtures.