Electronic Related Products

Applications in Wire Cut and CNC EDM machining industries

The application of Wire Cut and CNC EDM machines in electronic products typically results in products that people can directly touch and use. These products are not only diverse but also vary in function. To increase customer purchase intent, most electronic products not only enhance their internal functions but also require detailed texture processing and special design on their appearance, and moreover, effectively reducing costs to stand out among numerous products. EDM (Electrical Discharge Machine) and WEDM (Wire Cut Electrical Discharge Machine) play a key role in the mold manufacturing of electronic products.

EDM machines can precisely machine complex-shaped molds, such as mobile phone cases, laptop housings, and tablet back panels, which usually requires high precision and excellent surface quality. EDM machines can perform fine machining on high-hardness materials, ensuring the durability and precision of the molds.

Wire cutting machines are also widely used in mold manufacturing, such as for making keyboard key molds, camera lens molds, and precise parts for various electronic product housings. Wire cutting technology can achieve high-precision complex contour cutting and can process materials that are difficult to machine using traditional methods, ensuring dimensional accuracy and consistency of the molds.

Personal Computer

Liquid cooling system related components, Graphics card layout, PC case slots, Cooling fan, PC case ventilation holes, Rubber pads, Hardware jacks.

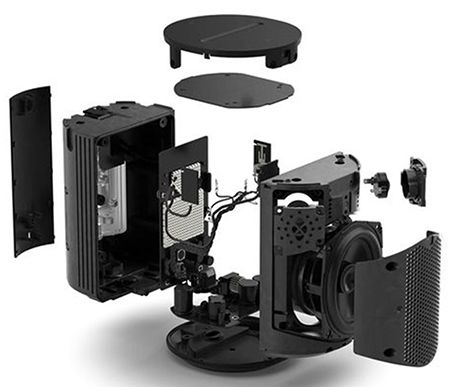

Speaker

Main body casing, Button switches, Holes for cooling or sound playback, Connectors, Small plastic assemble parts.