JSEDM CNC EDM Machines: High-Performance Electrical Discharge Machining Solutions

JSEDM's high-performance CNC Electrical Discharge Machines offer superior precision and automation for mold manufacturing and metalworking. With 40+ years of expertise, our CNC EDM solutions feature advanced control systems, exceptional machining efficiency, and versatile programming capabilities for complex 3D machining operations. Discover our Moving Table, Moving Column, and Double Head Column EDM technologies.

CNC EDM

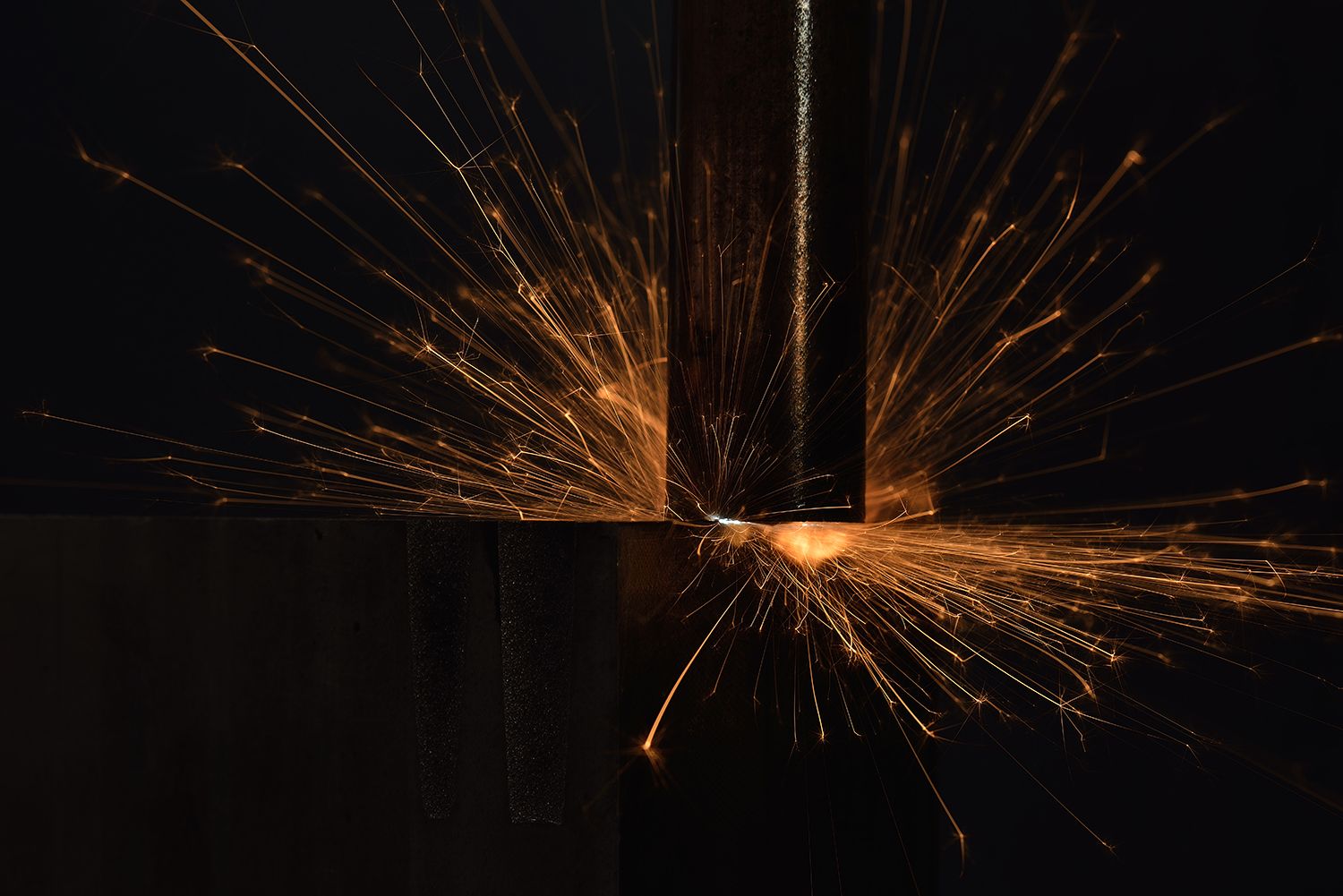

Also known as an electrical spark machine, can use copper or graphite as electrode to process various conductive materials. It is mostly used for processing plastic injection molds

CNC electrical discharge machine is a specialized tool used for electrical discharge machining, primarily for precision and complex mold processing in manufacturing. Its working principle involves using electrical sparks to remove material from the workpiece, achieving the desired shape, size, and surface finish. This method is particularly suitable for hard, conductive materials such as steel, aluminum, and copper.

CNC electrical discharge machines have precise control systems, enabling complex machining operations and improving production efficiency and product quality.

Both CNC electrical discharge machines and ZNC electrical discharge machines are types of electrical discharge machining, but there are some key differences between them. CNC electrical discharge machines have several advantages over ZNC electrical discharge machines such as the aspects listed below:

Automation and Precision:

- CNC Electrical Discharge Machines: CNC (Computer Numerical Control) electrical discharge machines have an automated control system that can execute machining tasks automatically according to predetermined programs, maintaining a high level of machining precision. They can perform complex three-dimensional machining and accurately repeat the machining process.

- ZNC Electrical Discharge Machines: ZNC (Z-Axis Numerical Control) electrical discharge machines rely mainly on manual operation, making the machining process more cumbersome and prone to human error. Their precision is generally lower than that of CNC electrical discharge machines.

Machining Efficiency and Flexibility:

- CNC Electrical Discharge Machines: Due to their automation and program control, CNC electrical discharge machines have higher machining efficiency and production capacity. Additionally, they offer greater machining flexibility, capable of adapting to various machining needs.

- ZNC Electrical Discharge Machines: Because of their reliance on manual operation, ZNC electrical discharge machines typically have lower machining efficiency and flexibility compared to CNC electrical discharge machines.

Program Control and Versatility:

- CNC Electrical Discharge Machines: CNC electrical discharge machines allow users to program complex machining operations, including shaking, vector, and multi-hole machining. They can store multiple machining programs, making it convenient for users to switch and use them as needed.

- ZNC Electrical Discharge Machines: ZNC electrical discharge machines have limited functionality, mainly used for basic electrical discharge machining and lacking the versatility of CNC electrical discharge machines.

Ease of Operation:

- CNC Electrical Discharge Machines: Although operating CNC electrical discharge machines may require some training, once familiarized, their interface and functions are more intuitive and convenient for users.

- ZNC Electrical Discharge Machines: The operation of ZNC electrical discharge machines is more basic, requiring less skill and training, but their functionality and flexibility are limited.

Working Principle of CNC Electrical Discharge Machine:

The principle of CNC electrical discharge machining is mainly based on the phenomenon of electrical spark discharge. When the distance between two conductive materials (the electrode and the workpiece) is reduced to a certain value and an electrolyte is present, a certain voltage and current create electrical spark discharges. This discharge energy instantly melts or oxidizes the material on the surface of the workpiece, achieving the effect of cutting or engraving.

How Can CNC EDM Technology Improve Your Mold Manufacturing Precision and Production Efficiency?

JSEDM's CNC Electrical Discharge Machines deliver exceptional precision with automated control systems that execute complex three-dimensional machining tasks with minimal human intervention. Our customers report up to 40% improvement in production efficiency and significantly reduced error rates compared to conventional ZNC machines. With programmable operations for shaking, vector, and multi-hole machining, you can achieve consistent quality across complex mold designs while reducing labor costs and production time. Contact us for a personalized consultation on how our CNC EDM solutions can transform your mold manufacturing operations.

What distinguishes JSEDM's CNC EDM technology is its comprehensive programming capabilities and operational flexibility. Our machines feature intuitive user interfaces that allow for complex machining operations including shaking, vector, and multi-hole processing, with the ability to store multiple machining programs for quick transitions between different production requirements. Available in Moving Table-Type, Moving Column-Type, and innovative Double Head Column Moving-Type configurations, our CNC EDM solutions deliver superior performance for plastic injection mold manufacturing, precision die-making, and specialized metalworking applications where conventional machining methods prove ineffective or inefficient.