JSEDM Wi-60E: High-Precision Flush-Type Wire Cut EDM Machine with 600/450/350mm XYZ Travel

JSEDM Wi-60E Flush-Type Wire Cut EDM delivers superior precision with 600/450/350mm XYZ travel and 0.5μm optical scale technology. Featuring a high-rigidity three-body structure, 15-inch touchscreen interface, and 212 machining parameters for optimal performance in mold manufacturing and automotive parts production. Experience exceptional cutting capability with minimal maintenance.

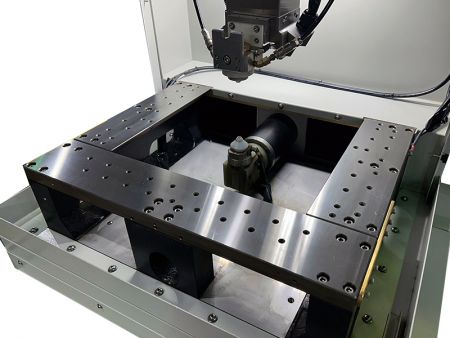

Flush-Type Wire Cut EDM XYZ Travel: 600 / 450 / 350

Wi-60E

Flush-Type Slow Feeding Wire Cut EDM

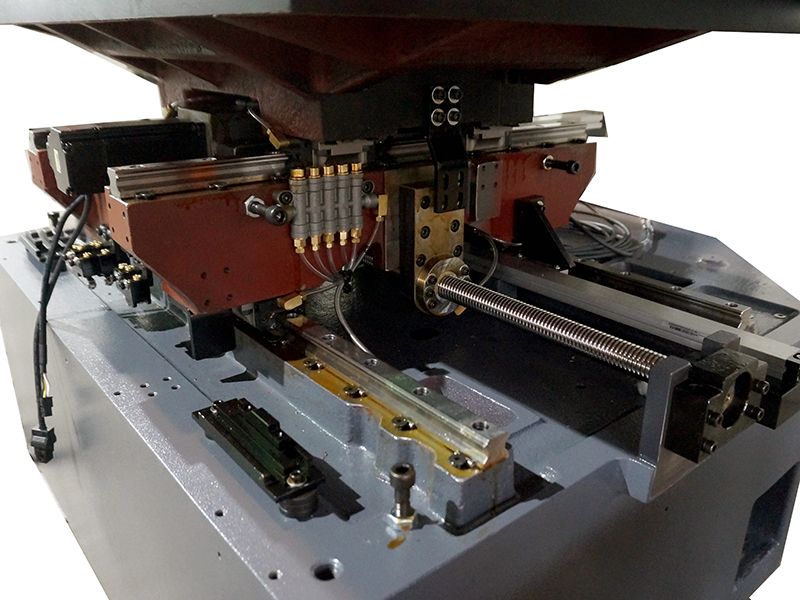

The Wi-60E is a flush-type wire EDM that shares similar features with the Wi-50E and has the same specifications as the Wi-640S. In addition to its characteristics of high-precision machining and ease of operation, this machine also emphasizes efficiency and durability. The Wi-60E uses high-quality components, such as PMI brand C2-grade screws and SP-grade linear guides, as well as Delta Electronics drives and servo motors, ensuring the machine's stability and durability. Moreover, the Wi-60E is particularly suitable for long-term continuous machining, maintaining a highly efficient and stable machining state, making it an ideal choice for producing high-quality workpieces.

Machine Introduction

The Wi-60E also features travel ranges of 600mm on the X-axis, 450mm on the Y-axis, 350mm on the Z-axis, 120mm on the U-axis, and 120mm on the V-axis, making it a high-performance, versatile wire EDM machine. The Wi-60E is suitable for a wide range of manufacturers and application scenarios, capable of meeting high-precision machining requirements, and improving production efficiency and product quality. Its user-friendly interface is easy to operate, making it suitable for various users, including beginners and experienced operators.

Regardless of size, the common cutting characteristic of flush-type machines is their ability to cut workpieces with a thickness of 30mm to 70mm, such as automotive parts, mold manufacturing, and tool processing. When the upper and lower machine head water nozzles are closely aligned with the workpiece, the cutting speed and precision are equivalent to those of submerge-type machines. Additionally, the Wi-60E has two features that are superior to the Wi-50E:

- First, the Wi-60E has a more powerful cutting capability, allowing it to handle larger and thicker workpieces, thereby expanding its range of applications.

- Second, the Wi-60E is equipped with a 0.5μm optical scale, which ensures the stability of machining accuracy, thereby improving the quality and precision of the machining process.

High-Rigidity Structure:

- The machine body utilizes CAE (Computer-Aided Engineering) to simulate structural deformation of each axis during actual operation. Therefore, we use a high-rigidity T-shaped machine body structure to reduce load and thermal deformation issues, ensuring permanent mechanical accuracy.

- Casting was made from Meehanite cast iron, stress-relieved through heat treatment, it features a high-rigidity, symmetrically balanced design to reduce load and thermal deformation.

- The overall transmission structure employs a high-power AC (400W) servo motor, paired with Taiwan's PMI ball screw and linear guides, this combination greatly reduces rotational errors. And with the adjustment of pitch compensation and backlash compensation in the control system, it ensures the precision of the machine's movement.

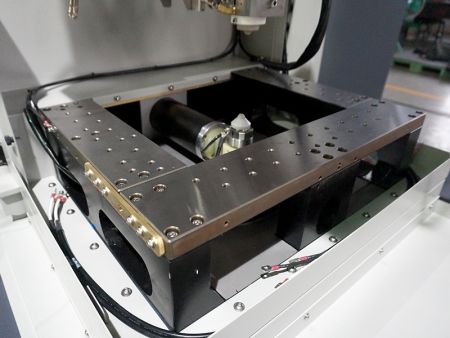

High-Precision Drive Shaft System:

The drive shaft uses highly precise "double nut" ball screws to achieve high rigidity, smooth operation, and minimal lead error. It is equipped with a high-torque, high-response AC (400W) servo motor, with an optional Fagor high-resolution optical scale for full closed-loop control. The optical scales are installed as close to the ball screws as possible, ensuring each axis maintains high precision, long life, and excellent stability.

Self-developed Wire Delivery System:

- The special structural design, combine with high-hardness ceramic pully, results in less wear and longer lifespan.

- With Japanese Panasonic AC servo motors, magnetic powder clutches, wire collection motors, and wire clamping mechanisms, the system can accurately make adjustment for instability caused by wire vibrations, ensuring stable wire delivery and low failure rates.

- The wire delivery system uses advanced constant tension motors for copper wire, it assures tension stability at all times and prevent copper wire entanglement caused by sudden breaks during normal operation.

- The wire delivery section utilizes a conduit-style collection structure. During threading, high-pressure fluid flow guides the copper wire to complete the threading process quickly within 3-5 seconds. Additionally, the use of high-quality ceramic wheel mechanisms ensures minimal wear over long-term use, eliminating the need for additional parts. Even ∅0.1mm copper wire can pass through easily without tangling.

Controller Performance and Features

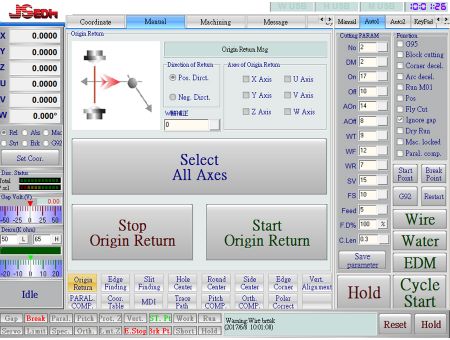

● Right-angle Compensation: This function compensates the right-angle and parallelism of the XY and UV planes of the wire cutting machine. After compensation, the machine's right-angle accuracy can reach within ±1.5μm/300mm.

● Five Types of Corner Assist Lines: Contains additional corner assist line functions compared to other wire cutting machines:

0 - Intersection point

1 - <90 degrees (tangent) => Additional function

2 - <90 degrees (arc) => Additional function

3 - Tangent => Additional function

4 - Arc => Additional function

● Fuzzy G95 Control: Achieves more than 95% of manual operation speed, or even better.

● 212 Sets of Ultra-fine Machining Parameters: Provide 212 sets of ultra-fine machining parameters that can be adjusted according to different cutting needs.

● 10 Sets of Arc Deceleration Machining Parameters: Automatically switches machining parameters according to the arc radius set by the user.

● 10 Sets of Corner Deceleration Machining Parameters: Automatically switches machining parameters according to the corner angle set by the user.

● Ethernet Access Interface: Provides an Ethernet interface for accessing large amounts of machining data.

● 100 Sets of Coordinate System Records (Including G54 ~ G59): Traditional wire cutting systems only provide 6 sets of coordinate records (G54 ~ G59). JSEDM Wire Cutting System offers up to 100 sets of coordinate system records, which can be used for positioning movements.

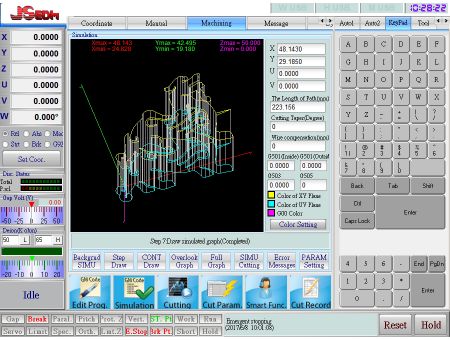

● Dynamic 3D Graphical Display: Simulates graphics in 3D and allows zooming, regional enlargement, and rotation for detailed viewing.

● Touch Operation Interface: Uses a 15-inch high-resolution industrial-grade touch screen with an intuitive interface, significantly reducing operator learning time.

● Simple Operation Interface: Compared to the traditional DOS multi-layer operation menu, the Wire Cutting System simplifies the operation interface significantly and adds a hotkey area to centralize commonly used function keys, effectively reducing learning time and operation difficulty.

● Simplified Calibration Steps: Most functions only require 2-3 steps to start the calibration process, this simplifies the operation flow and shortening calibration time.

● Maintenance Information: Records six types of maintenance information, timely reminding the operator to replace consumables. The maintenance information includes: 1. Copper wire usage length, 2. Waste wire bucket usage time, 3. Water tank filter usage time, 4. Electron feeder usage time, 5. Ion exchange resin usage time, 6. Workbench usage time.

● POS Function: When this function is activated during machining, it automatically speeds up the machine when the workpiece is not in its path and resumes the machining speed once it touches the workpiece and cutting starts. This function greatly reduces machining time.

Product Specification

| Technical Spec. | |||

|---|---|---|---|

| Machine Type | Flushing | Drivetrain | 5 axis AC servo system |

| Mechanical Structure | Three-Body Independent | Simulations Axis | XYUV (4 axis) |

| Max. Workpiece Size L x W x H (mm) | 110 x 650 x 340mm | Wire Diameter Range | Φ 0.10 ~ 0.3mm |

| Max. Workpiece Weight | 1000kgs | Max. Taper Angle | ± 22.5° (Thickness 100mm) |

| X Axis Travel (Right-Left) | 600mm | Max. Axis Load | 10kgs |

| Y Axis Travel (Front-Back) | 450mm | Conductivity | Automatic |

| Z Axis Travel | 350mm | Water Tank Capacity | 300L |

| U Axis Travel | 100mm | Dimension (W x D x H) | 3000 x 2650 x 2250mm |

| V Axis Travel | 100mm | ||

- Gallery

- 2.5D image simulation allows customers to easily track the current cutting status, especially in taper cutting and abnormal shape with upper-lower shape difference.

- Multi-functional calibration interface equipped with graphical explanations, making it easy for users to learn and operate.

- Time-based maintenance records enable customers to replace consumables at routine time, enhancing machining stability.

- Time-based maintenance records enable customers to replace consumables at routine time, enhancing machining stability.

- With machining parameter data sheet, customers can refer to built-in parameters and select suitable machining conditions based on wire diameter, number of machining passes, and material type.

How does the Wi-60E's structural design impact mold manufacturing precision?

The Wi-60E's T-shaped Meehanite cast iron body, designed using CAE simulation, delivers exceptional rigidity that virtually eliminates thermal deformation during precision mold cutting. Combined with the 0.5μm optical scale and stress-relieved construction, it maintains ±1.5μm/300mm right-angle accuracy even during extended operations—critical for complex mold components with tight tolerances. This structural superiority translates directly to higher-quality finished products and reduced scrap rates.

Equipped with a 0.5μm optical scale and high-performance 400W AC servo motors, the Wi-60E delivers superior machining stability even during extended operations. The intuitive 15-inch touch interface combined with 212 sets of ultra-fine machining parameters enables operators to achieve exceptional surface finishes down to micron-level precision. Advanced features including right-angle compensation, fuzzy G95 control, and dynamic 3D graphical display significantly enhance productivity while reducing operation complexity. The system's high-quality components—including PMI ball screws, ceramic wire delivery mechanisms, and Delta Electronics drives—ensure long-term reliability and minimal maintenance requirements for continuous production environments.