JSEDM EB1060L Column Moving-Type CNC EDM Machine - 1000/600/500mm XYZ Travel

JSEDM's EB1060L Column Moving-Type CNC EDM delivers exceptional precision for medium-sized automotive molds with 1000/600/500mm XYZ travel. Features high-rigidity structure, AI automatic indexing, and optional 90A machining current. Ideal for radiator molds, headlights, and complex automotive components.

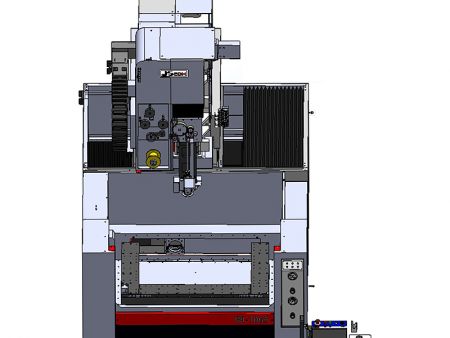

Column Moving-Type CNC EDM XYZ Travel 1000 / 600 / 500

CNC-EB1060L

Column Moving-Type CNC Electrical Discharge Machine

The EB1060L is a larger specification moving column type CNC EDM machine that shares the same high-quality components, powerful performance, and versatile machining capabilities as the EB750L. Whether for large, complex workpieces or small, precise components, the EB1060L delivers high-quality, efficient machining solutions. Its specification advantages make it an ideal choice for machining medium-sized automotive parts.

Machine Introduction

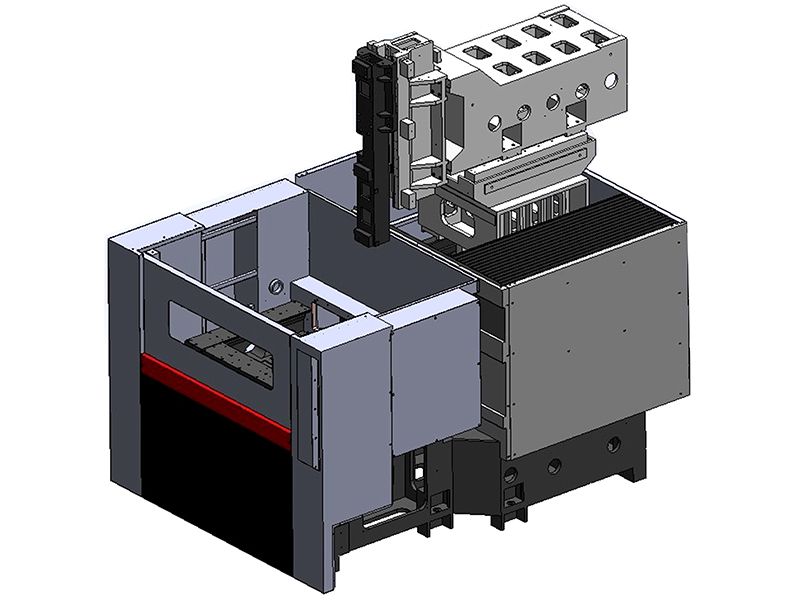

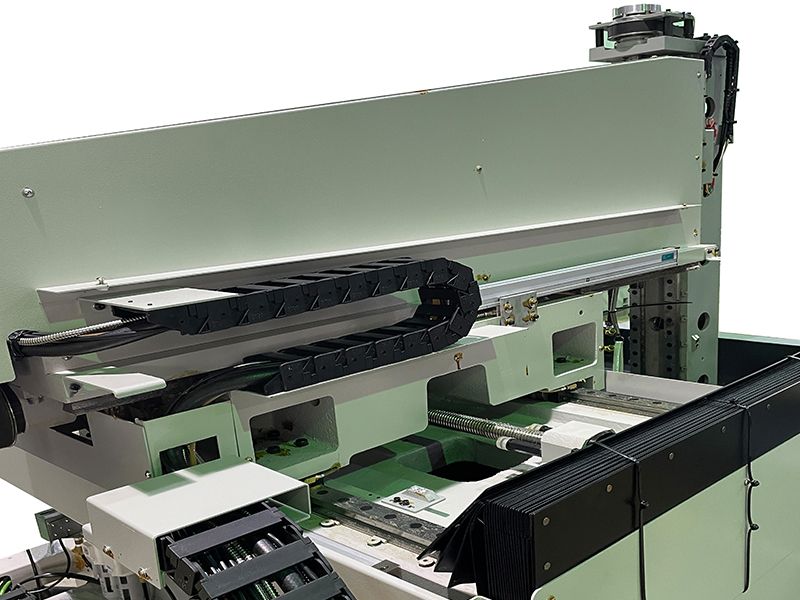

The EB1060L is a moving column structure CNC EDM machine with an X-axis travel of 1000mm, Y-axis travel of 600mm, Z-axis travel of 500mm, and a worktable size of 1250 x 750mm. It is equipped with a rear counterweight, ensuring Z-axis stability regardless of the electrode weight. Customers can choose between oil flushing or oil immersion processing methods based on their needs.

The EB1060L features precision-grade screws, linear guides, and high-quality SENYO DENKI servo motors, complemented by a 1μm optical scale to ensure high precision and machining stability. The moving column structure design provides greater travel space and stability, enabling the EB1060L to handle various complex workpieces, particularly medium-sized automotive parts.

The EB1060L has a wide range of applications. Below are some examples:

- High-End Automotive Radiator Molds: These often require side discharge machining, which reduces electrode wear and increases durability. The EB1060L's powerful machining capabilities and high precision ensure accurate forming and stability of radiator molds.

- Car Headlight Molds: These workpieces require multi-directional machining. The EB1060L's versatile performance allows it to meet these demands, including oscillation, side discharge, and vector machining. These methods ensure the mold's accuracy and surface quality.

- Automotive Batteries: As a critical component of vehicles, certain grooves on the battery's exterior require EDM to form. The EB1060L's EDM capability can precisely machine these complex grooves, ensuring both the battery's perfect appearance and functionality.

High-Rigidity Structure:

- The machine adopts a high-rigidity moving column structure capable of supporting workpieces up to 4500 kgs, reducing issues related to machine load and thermal deformation, thereby ensuring long-term precision.

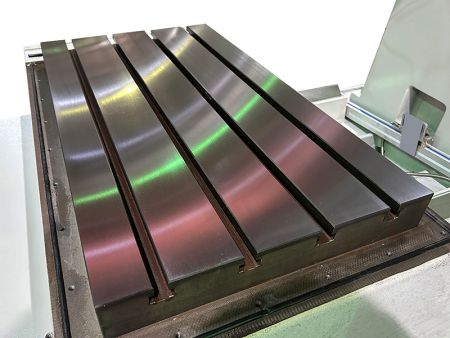

- Made from Meehanite cast iron, the machine undergoes stress-relief heat treatment, providing a high-rigidity, symmetrically balanced base design. The worktable is heat-treated and precision-ground, making it wear-resistant and maintaining flatness even under heavy loads.

- The base design utilizes a moving column (bullhead type) structure, ensuring that the flatness of the workpiece on the table is not affected during movement, delivering optimal working precision. The robust base design prevents deformation even when subjected to long-term heavy loads.

Wide Linear Guide Span and Precision Ball Screw:

- The X and Y axes utilize low-friction linear guides, ensuring machine precision and smooth operation during its movement. The wide linear guide and span ensure accurate positioning and feed data during long-term back-and-forth and side-to-side movements, especially during reaming and vector machining, maintaining the machine's precision (backlash value) over time.

- The X-axis linear guide (Ψ 30mm) is mounted on the machine's middle base, ensuring flatness during installation and extending the lifespan of the guide, thereby maintaining machine accuracy.

- The Y-axis linear guide (Ψ 30mm) is installed on the machine's upper base, ensuring flatness during installation and lightness (without bearing weight) to reduce friction and extend the lifespan, thus permanently ensuring machine accuracy.

- The X-axis (Ψ 32mm) and Y-axis (Ψ 32mm) utilize precision-grade ball screws combined with low-friction linear guides to ensure machine accuracy.

Precision Spindle:

- The spindle section features an integrally cast design to ensure stability during large electrode machining. It also utilizes alloy steel guides (Ψ 30mm) combined with roller bearings, minimizing friction and ensuring spindle feed accuracy.

- The spindle tower is equipped with a 400W servo motor, making the spindle operation more lightweight (without counterweights) while ensuring precise displacement during operation and extending the lifespan of the ball screw (Ψ 25mm).

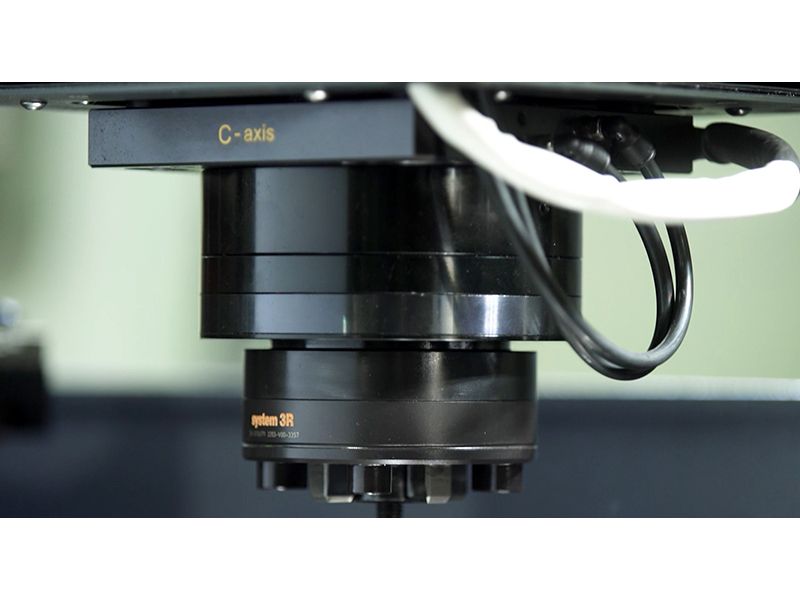

C-axis Features and Applications:

- The C-axis offers high-precision positioning capability, allowing for accurate positioning and rotation of parts during machining. This enables more precise machining and better results when working on parts that require rotational machining.

- The C-axis can perform indexing machining, which involves machining at fixed angles. This is particularly useful for parts requiring periodic or repetitive machining, improving consistency and efficiency.

- For parts with complex thread structures, the C-axis can facilitate thread machining. These thread structures may have unique shapes that require machining at various angles, and the rotational function of the C-axis allows for precise thread machining.

Automatic Tool Changer (ATC) and the Advantages of Automation:

- Allows quick and precise tool changes, reduces tool change time and thereby increasing machining efficiency.

- Ensure that it is precise in every tool change, avoiding errors caused by human factors, which in turn improves machining accuracy.

- Can automatically complete tool changes during the machining process, reducing downtime and increasing machine uptime.

- Minimizes the need for manual intervention, reducing labor requirements while also lowering the risk of errors and accidents caused by human operation.

Controller Performance and Features

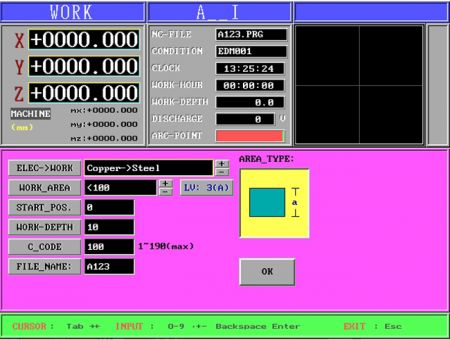

● Automatic Indexing: The system allows users to directly select material type and area, input machining depth and starting height, and then automatically search for the optimal conditions to generate the machining program. Users can also edit and save the generated program, which can be reloaded for future use without altering the original database content.

● High-Efficiency Discharge Module: The discharge circuit uses MOSFET transistors and a fast discharge device (POWER SINK) to enhance machining efficiency and reduce electrode wear. The machining circuit employs FPGA IC components for faster monitoring of discharge conditions (up to single discharge waveform monitoring), providing more effective prevention of carbon buildup (ARC). Users can set ARC voltage levels, ARC time, and ARC sensitivity to further improve machining efficiency. Additionally, it offers two-stage gap and two-stage off-time functions to assist users in automatically adjusting machining parameters when ARC occurs, leading to better machining efficiency. These features and designs aim to improve machining efficiency, reduce wear, and provide better operability and stability.

● Servo Control: The servo control system uses DSP digital processing, allowing for faster response times, with loop control occurring every 0.2ms, which is faster than the typical 1ms or more response time of PC-based controllers. This characteristic enhances spindle stability during machining, ensuring smoother machine operation.

Additionally, the CNC EDM machine offers a multi-stage debris removal mode, suitable for deep hole machining and thin sheet processing, providing more flexible machining options.

Moreover, the servo protection function is an important feature that prevents electrode damage caused by improper user operation, such as mold crushing. This protection function ensures the safety and longevity of the electrode during the machining process.

These combined features make the CNC EDM machine's servo control more flexible, stable, and safe, capable of meeting various machining demands while ensuring high-quality machining results.

Product Specification

| Technical Spec. | |||

|---|---|---|---|

| Mechanical Structure | Column Moving-Type | Distance Between Platen to Table | 950mm |

| Work Tank Capacity L x W x H (mm) | 1900 x 1100 x 620mm | Optical Scale Display | 1um |

| Work Table Size | 1250 x 750mm | Max. Machining Current | 60A 90A (Optional) |

| X Axis Travel (Right-Left) | 1000mm | ||

| Y Axis Travel (Front-Back) | 600mm | Min. Electrode Wear Ratio | 0.12% |

| Z Axis Travel | 500mm | Machine Weight | 5200kgs |

| Max. Workpiece Weight | 4500kgs | Fluid Tank Capacity | 1600L |

| Max. Electrode Weight | 350kgs | Machine Outside Dimensions (W x D x H) | 3600 x 3250 x 3200mm |

- Gallery

- In this interface, you can input various machining programs such as vector machining, orbiting, side placement, and rectangular processing.

- The AI automatic indexing function allows users to directly select the material and area to be machined. After inputting the machining depth and starting height, the system automatically searches for the optimal conditions.

- The one-page multifunctional calibration includes edge finding, inner hole finding, outer circle finding, vertex finding, and circle center finding.

- When the fire sensor detects flames, it sends an alarm signal and pauses the machine to prevent a fire from occurring.

- When the worktable catches fire due to excessive oil temperature, the fire extinguisher is activated to extinguish the fire, providing a second layer of protection beyond the fire sensor.

- The adjustable electrode head allows for quick electrode replacement and adjustments for parallelism and verticality.

- The three-jaw chuck allows dielectric fluid to pass directly through the jaws and flow along the electrode into the mold, enhancing debris removal efficiency.

- The vertical filter cartridge design makes it easy to replace the filter and prevents the filter from breaking during replacement, avoiding spills of oil and metal debris.

How Can the EB1060L's Column Moving Structure Improve Automotive Radiator Mold Production?

The EB1060L's moving column design provides unmatched stability for radiator mold machining, maintaining precision even with 4500kg workloads. Its T-shaped structure prevents worktable deviation while the Meehanite cast iron construction withstands thermal deformation during extended operations. This translates to 30% higher precision for complex radiator molds with fine details and consistent quality across production runs.

Equipped with advanced AI automatic indexing and a high-efficiency discharge module utilizing MOSFET transistors, the EB1060L delivers superior machining efficiency with minimal electrode wear. The comprehensive safety features include fire sensors and automatic extinguishing systems, while the user-friendly controller offers intuitive programming for vector machining, orbiting, and rectangular processing. Ideal for automotive radiator molds, headlight components, and battery casings, this machine excels in applications requiring multi-directional machining with consistent precision. Optional features such as the C-axis for rotational machining and Automatic Tool Changer (ATC) further enhance productivity for demanding manufacturing environments.