JSEDM CNC-EB540L: Moving Table-Type CNC EDM Machine with 500/400/350mm XYZ Travel

JSEDM CNC-EB540L is an economical moving table-type CNC EDM machine with 500/400/350mm XYZ travel, ideal for light molds and precision components. Featuring high-rigidity T-shaped structure, Japanese servo motors, and advanced controller with AI indexing, it delivers exceptional machining accuracy with minimal electrode wear at 0.12%.

Moving Table-Type CNC EDM XYZ Travel 500 / 400 / 350

CNC-EB540L

Moving Table-Type CNC Electrical Discharge Machine

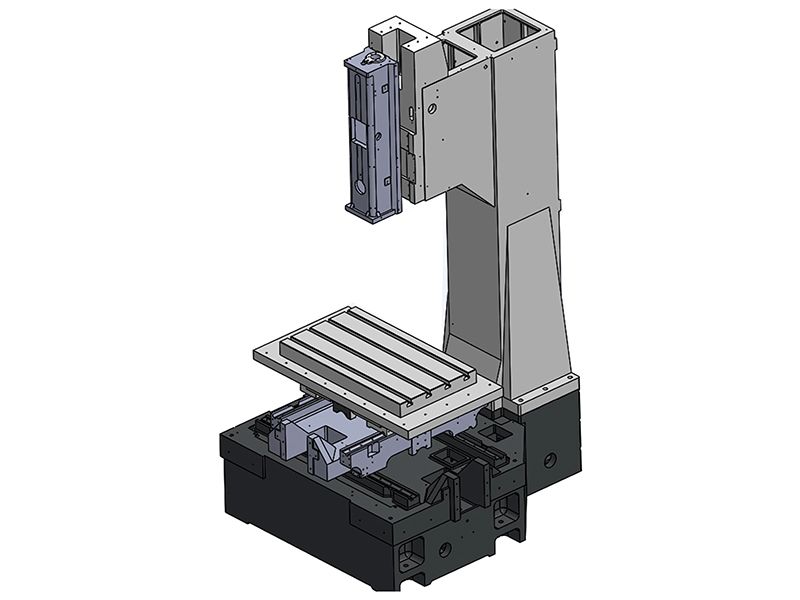

The EB540L is a high-performance CNC EDM machine, an upgraded version of the EB600L model, offering greater machining capability and a broader range of applications. Like the EB600L, the EB540L features a C-type casting structure to ensure stability and rigidity of the machine body. Key components, such as precision-grade ball screws, linear guides, and other high-quality parts, are consistent with those in the EB600L, ensuring accuracy and reliability during machining.

The specifications of the EB540L include XYZ axis travel and worktable size, enabling it to handle larger workpieces and molds. This makes it an ideal choice for processing a wide range of workpieces, from small parts to medium-sized components, with ease. Its high-performance machining capabilities and robust structure allow the EB540L to excel in industrial processing, meeting customers' demands for high-precision and high-efficiency machining.

Machine Introduction

The EB540L is a high-performance CNC EDM machine with an X-axis travel of 500mm, a Y-axis travel of 400mm, a Z-axis travel of 350mm, and a worktable size of 800mm x 450mm. This makes it particularly suitable for handling small to medium-sized molds and workpieces.

The machine is equipped with a high-quality servo motor from Japan's SANYO DENKI and a 1μm optical scale, ensuring machining accuracy and stability. The XYZ travel of the EB540L is similar to that of the moving-column type EB5435L, making it suitable for processing molds of the same travel but with lighter weight, offering a high-efficiency and high-quality machining solution.

The EB540L has a wide range of applications. Below are some of the examples:

- Adjustable Nozzle Mold: Commonly used in industrial and household nozzle devices. The EB540L can precisely machine each part of the nozzle, ensuring the proper functioning of its adjustable features.

- Terminal Block Mold: Sometimes used in industrial wiring applications. These molds usually have multiple interfaces that require precise machining to ensure reliable connections. The EB540L’s matrix machining function can quickly and accurately handle this type of mold.

- Handle Mold for Hand Tool: Which needs to be ergonomically designed to provide a good grip and comfort. The EB540L can shape the handle using matrix machining and process the thread parts using the oscillation function, ensuring that the handle meets both functional and aesthetic requirements.

All three examples above involve molds designed for multi-cavity output, requiring matrix and oscillation functions for machining. The EB540L's high precision, efficiency, and versatile machining capabilities make it an ideal choice for handling such molds.

High-Rigidity Structure:

- The machine body structure utilizes CAE (Computer-Aided Engineering) to simulate structural analysis of each axis during actual operation. Therefore, we have adopted a high-rigidity T-shaped body structure to reduce load and thermal deformation issues, ensuring long-term precision of the machine.

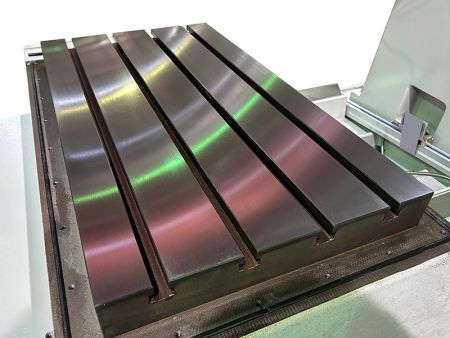

- Made from Meehanite cast iron and stress-relieved through heat treatment, the structure features a high-rigidity, symmetrically balanced design, which helps reduce load and thermal deformation.

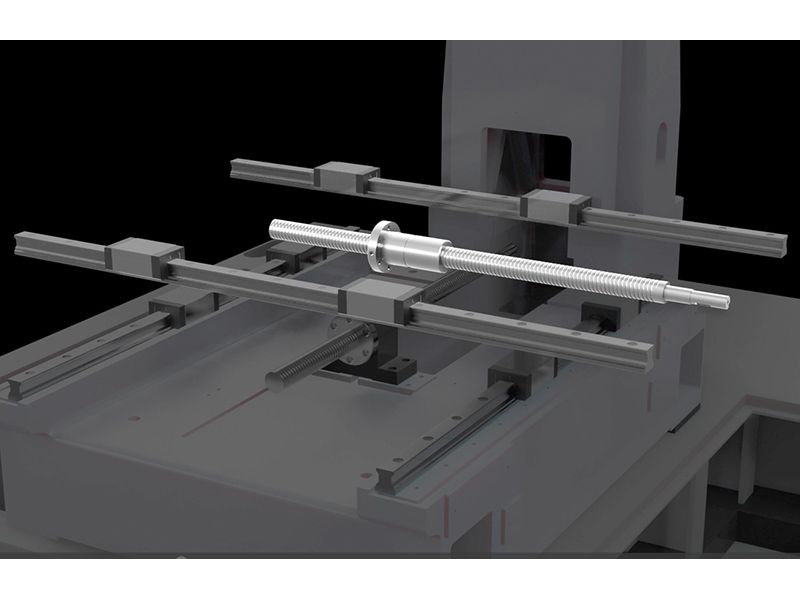

XYZ-Axis Travel Structure:

- The X, Y, and Z axis use low-friction linear guides and ball screws, ensuring precision even under heavy loads while allowing for agile operation during machining. This design guarantees both accuracy and flexibility throughout the machining process. Additionally, the wide span of the linear guides ensures that the parallelism of the worktable remains unaffected during movement in any direction under load, thereby ensuring machining quality and stability.

- A belt-driven servo system is employed to reduce the size of the machine. By utilizing gear ratio, even a low-wattage servo motor can drive the entire machine, meeting energy-saving requirements. This design not only enhances the machine's operational efficiency but also reduces energy consumption, aligning with environmental and energy-saving goals.

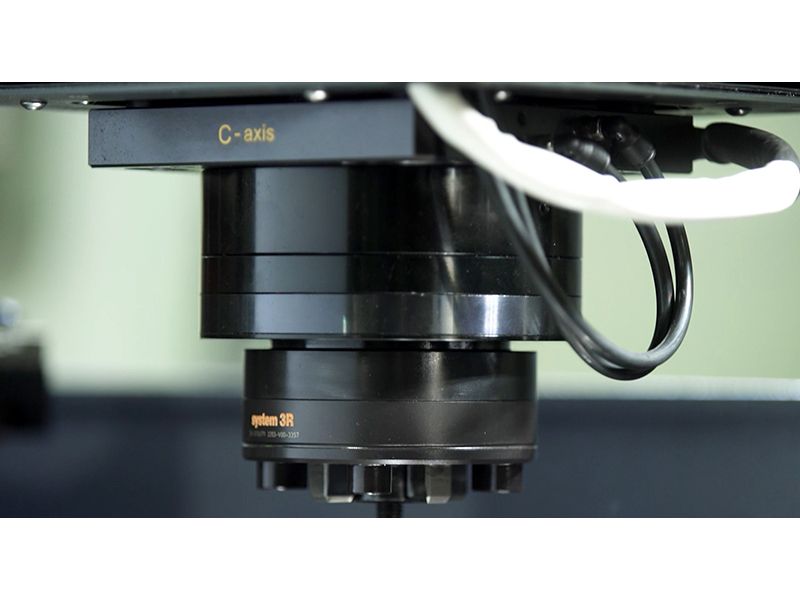

Features and Applications of the C-axis:

- The C-axis features high-precision positioning capabilities, enabling accurate positioning and rotation of parts during machining. This allows for more precise machining and better results, especially when processing parts that require rotational machining.

- The C-axis can achieve indexed machining, allowing parts to be machined at fixed angles. This function is particularly useful for parts that require periodic or repetitive machining, significantly improving consistency and efficiency.

- For parts with complex thread structures, the C-axis can perform thread and complex shape machining. If the part has special-shaped threads that need to be machined at different angles, the rotational capability of the C-axis can precisely achieve the required shapes.

Automatic Tool Changer (ATC) and the Advantages of Automation:

- Allows quick and precise tool changes, reduces tool change time and thereby increasing machining efficiency.

- Ensure that it is precise in every tool change, avoiding errors caused by human factors, which in turn improves machining accuracy.

- Can automatically complete tool changes during the machining process, reducing downtime and increasing machine uptime.

- Minimizes the need for manual intervention, reducing labor requirements while also lowering the risk of errors and accidents caused by human operation.

Controller Performance and Features

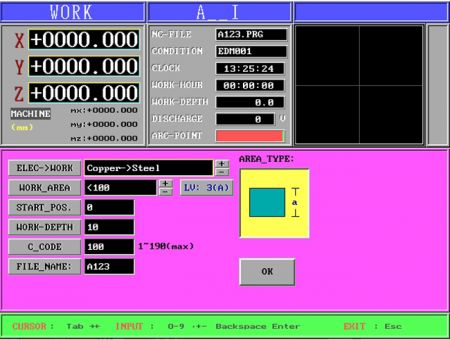

● Automatic Indexing: The system allows users to directly select material type and area, input machining depth and starting height, and then automatically search for the optimal conditions to generate the machining program. Users can also edit and save the generated program, which can be reloaded for future use without altering the original database content.

● High-Efficiency Discharge Module: The discharge circuit uses MOSFET transistors and a fast discharge device (POWER SINK) to enhance machining efficiency and reduce electrode wear. The machining circuit employs FPGA IC components for faster monitoring of discharge conditions (up to single discharge waveform monitoring), providing more effective prevention of carbon buildup (ARC). Users can set ARC voltage levels, ARC time, and ARC sensitivity to further improve machining efficiency. Additionally, it offers two-stage gap and two-stage off-time functions to assist users in automatically adjusting machining parameters when ARC occurs, leading to better machining efficiency. These features and designs aim to improve machining efficiency, reduce wear, and provide better operability and stability.

● Servo Control: The servo control system uses DSP digital processing, allowing for faster response times, with loop control occurring every 0.2ms, which is faster than the typical 1ms or more response time of PC-based controllers. This characteristic enhances spindle stability during machining, ensuring smoother machine operation.

Additionally, the CNC EDM machine offers a multi-stage debris removal mode, suitable for deep hole machining and thin sheet processing, providing more flexible machining options.

Moreover, the servo protection function is an important feature that prevents electrode damage caused by improper user operation, such as mold crushing. This protection function ensures the safety and longevity of the electrode during the machining process.

These combined features make the CNC EDM machine's servo control more flexible, stable, and safe, capable of meeting various machining demands while ensuring high-quality machining results.

Product Specification

| Technical Spec. | |||

|---|---|---|---|

| Mechanical Structure | Moving Table | Distance Between Platen to Table | 635mm |

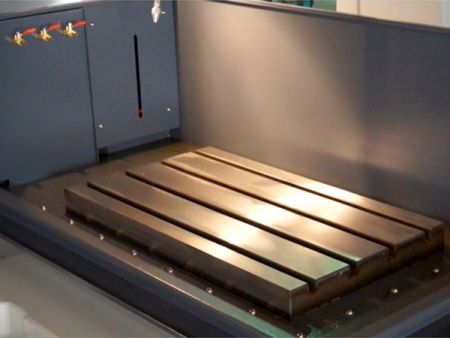

| Work Tank Capacity L x W x H (mm) | 1170 x 690 x 425mm | Optical Scale Display | 1um |

| Work Table Size | 1100 x 630mm | Max. Machining Current | 60A 90A (Optional) |

| X Axis Travel (Right-Left) | 500mm | ||

| Y Axis Travel (Front-Back) | 400mm | Min. Electrode Wear Ratio | 0.12% |

| Z Axis Travel | 350mm | Machine Weight | 1950kgs |

| Max. Workpiece Weight | 1350kgs | Fluid Tank Capacity | 370L |

| Max. Electrode Weight | 200kgs | Machine Outside Dimensions (W x D x H) | 3600 x 1340 x 2500mm |

- Gallery

- In this interface, you can input various machining programs such as vector machining, orbiting, side placement, and rectangular processing.

- The AI automatic indexing function allows users to directly select the material and area to be machined. After inputting the machining depth and starting height, the system automatically searches for the optimal conditions.

- The one-page multifunctional calibration includes edge finding, inner hole finding, outer circle finding, vertex finding, and circle center finding.

- When the fire sensor detects flames, it sends an alarm signal and pauses the machine to prevent a fire from occurring.

- When the worktable catches fire due to excessive oil temperature, the fire extinguisher is activated to extinguish the fire, providing a second layer of protection beyond the fire sensor.

- The adjustable electrode head allows for quick electrode replacement and adjustments for parallelism and verticality.

- The three-jaw chuck allows dielectric fluid to pass directly through the jaws and flow along the electrode into the mold, enhancing debris removal efficiency.

- The vertical filter cartridge design makes it easy to replace the filter and prevents the filter from breaking during replacement, avoiding spills of oil and metal debris.

How does the EB540L's 0.12% electrode wear ratio impact your automotive parts production costs?

The EB540L achieves an industry-leading 0.12% electrode wear ratio through its advanced high-efficiency discharge module with MOSFET transistors and fast discharge technology. For automotive parts manufacturers, this translates to dramatic cost savings by extending electrode life up to 5 times longer than conventional EDM systems. When producing complex automotive components requiring multiple electrodes, this minimal wear significantly reduces both material costs and production downtime associated with electrode replacement, directly improving your bottom line and production capacity.

What sets the EB540L apart is its advanced controller with AI automatic indexing and high-efficiency discharge module using MOSFET transistors, resulting in minimal electrode wear ratio of just 0.12%. The machine's robust design supports workpieces up to 1350kg while maintaining precision across various applications including adjustable nozzle molds, terminal blocks, and hand tool handle molds. With comprehensive safety features including fire sensors and automatic extinguishers, plus user-friendly features like the vertical filter cartridge design and adjustable electrode head, the CNC-EB540L delivers the perfect balance of performance, precision, and value for modern manufacturing operations.